Pulse Starches

Producing Pulse Starch

-

Starch represents the major component of peas, lentils, beans and chickpeas, ranging from 40-50% of the dry seed weight. Starches can either be isolated from pulses using wet processing techniques, or concentrated during air classification to produce a coarse, starch-rich product. Wet methods to isolate starch are able to achieve much higher levels of purity (>85%) compared to air-classified products which will typically range from 65-85% and contain anywhere from 8-20% of the remaining seed constituents such as protein and fibres.

-

Pulse Starch Composition

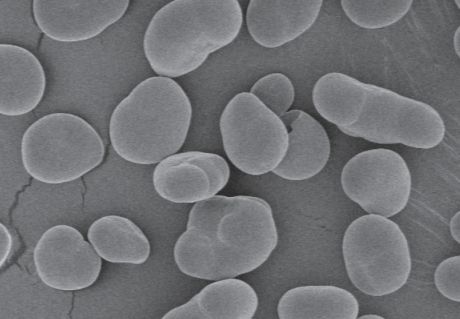

Starches naturally occur as granules that are composed of chains of glucose units linked together to form the two building blocks of starch: amylose and amylopectin. The ratio of amylose:amylopectin plays an important role in starch functionality.

Compared to many other naturally occurring starches, pea, lentil and bean starches contain very high levels of amylose (29 – 50%) and contain low concentrations (<1%) of minor components such as lipids or proteins (Hoover et al., 2010).

Starch content and composition of pulses1

| Pulse | Starch (%db) | Amylose (%starch) |

|---|---|---|

| Pea | 45.7 - 51.2 | 31 – 49 |

| Lentil | 44.5 - 50.1 | 29 – 29 |

| Faba Bean | 40.8 - 47.2 | 31 – 40 |

| Corn | 70.0 - 75.02 | 26 - 31 |

| Tapioca | 84.53 | 16 - 31 |

1. Adapted from Ren et al. 2021. 2. Prasanthi et al. 2017. 3. Sanchez et al. 2010.

Functionality and Applications

Pulse starches are clean-label, functional ingredients. The higher amylose content of pulse starches allows them to form highly-stable gel networks. Pulse starches display reduced gelatinization temperatures and granular swelling which results in a lower peak viscosity under typical pasting conditions. Upon cooling, the reassociation of amylose in pulse starch allows for the formation of a strong gel. Pulses starches also exhibit greater resistance to enzymatic activity, high-temperature processing and slow digesting, contributing to a low glycemic index.

Food & Beverage

Pea starch can be used as a thickener, gelling agent, stabilizer, fat substitute, expansion agent, anti-caking agent and can provide crispiness and a smooth mouthfeel.

-

- Sweeteners

- Edible Films

- Sauces, Soups, Dressings and Condiments

- Snacks and Breakfast Cereals

- Baked Goods

-

- Processed Meats

- Seafood and Meat Substitutes

- Confectionary

- Noodles and Pasta

- Chilled and Shelf-Stable Dairy and Dairy Alternatives

Industrial Applications

-

- Oil & Ore Refining

- Medical Wound Dressings

- Bioplastics

- Pharmaceuticals

- Paper, Pulp & Packaging

Modifying Starches to Improve Functionality

Modifications can be applied to pulse starch to improve functionality for different end use applications, including:

-

- Enzymatic modification

- Chemical modifications:

- Acid thinning

- Oxidation

- Cross linking

- Substitution

-

- Physical modifications:

- High hydrostatic pressure treatment

- Hydrothermal treatments

- Irradiation

- Ultrasonication

- Physical modifications:

1. Ren, Y, Yuan, TZ, Chigwedere, CM, Ai, Y. A current review of structure, functional properties, and industrial applications of pulse starches for value-added utilization. Compr Rev Food Sci Food Saf. 2021; 20: 3061– 3092. https://doi.org/10.1111/1541-4337.12735

2. Prasanthi PS, Naveena N, Vishnuvardhana Rao M, Bhaskarachary K. Compositional variability of nutrients and phytochemicals in corn after processing. J Food Sci Technol. 2017 Apr;54(5):1080-1090. doi: 10.1007/s13197-017-2547-2. Epub 2017 Feb 18. PMID: 28416857; PMCID: PMC5380630.

3. Sánchez T, Dufour D, Moreno IX, Ceballos H. Journal of Agricultural and Food Chemistry 2010 58 (8), 5093-5099DOI: 10.1021/jf1001606