Meat

Pulses and pulse ingredients can be used in meat analogues and in meat products as blends, coatings, extenders and to improve the sustainability profile.

Using Pulse Ingredients in Meat Applications

-

The demand for more sustainable foods has led to new innovations in the meat sector with the emergence of 100% plant-based products, as well as blended meat formulations that contain both animal and plant ingredients. Meat blends leverage the strong sustainability profile of pulses to improve the footprint of meat products.

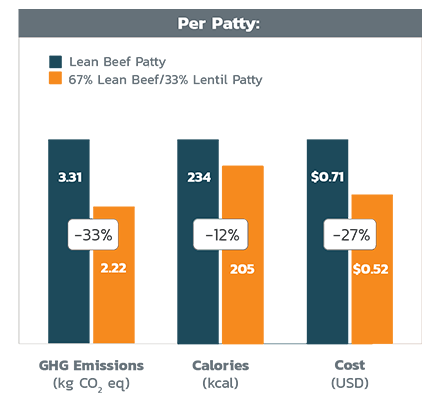

In a recent study, a blended burger patty consisting of 67% beef and 33% Canadian lentils was compared to an all-beef patty for both nutritional profile and environmental footprint. The blended burger was improved in both measures as well as in cost.

-

Functional Considerations

Pulses have been demonstrated to be effective in different meat products such as meat alternatives, burger patties, meat balls, low-fat bologna and sausages. The functionality of pulse ingredients can improve meat products in a variety of ways:

Pulse Ingredients as Binders

Due to their water and oil-binding capacities, pulse ingredients can reduce cooking losses in meat products. Pulses act as binders to help retain juiciness in the final product by lowering the amount of water and fat that is expelled during cooking. This water retention property also has benefits during the freeze/thaw cycle of frozen meat products. When used as binders, pulses maintain the taste and the colour integrity of the final product.

Pulse Ingredients as Coatings

Pulse ingredients are a more nutritionally-dense and clean label alternative to traditional coating and batter ingredients such as modified corn starch. In addition, they may provide some important functional advantages to fried meat products. Research conducted at the Manitoba Food & Product Development Centre showed a pea-based coating prolonged crispness and textural integrity of chicken nuggets stored under a heat lamp.

Extenders

Extenders replace a portion of meat in the finished product, resulting in cost savings. By using pulse ingredients, which are high in protein, this savings can be achieved without affecting the final protein content of the product. In addition, adding pulse ingredients can improve the sustainability profile.

Fat Reduction

Using pulse ingredients can help reduce the amount of fat needed in the meat product. In addition to improving the nutritional profile of the product, this can also assist with cost reduction as the majority of fat can be replaced by water.

Pulse Ingredient Considerations

Pulse ingredients have favourable properties important to consider when formulating meat products such as water and oil holding capacity, protein and fibre content, and lipoxygenase activity. Studies have shown that dry heat treatment of lentil flours using micronization technology can deactivate enzymes responsible for oxidation (lipoxygenase, peroxidase and glutathione reductase). Consequently, including micronized lentil flours in meat burger formulations delayed oxidation and prolonged redness during refrigerated and frozen storage of raw burgers and reduced off-flavours in cooked burgers.